Vitillo Hydraulic Hoses: Engineered for Excellence

Among hydraulic hose brands worldwide, Vitillo stands out for meeting numerous international quality standards and is highly regarded in the market, particularly for products manufactured in Italy. This product line features premium materials, exceptional durability, and excellent resistance to pressure, temperature, and chemicals.

International Quality Certifications Achieved by Vitillo:

- ISO 9001:2015 Quality Management System: Vitillo adheres to stringent manufacturing processes and quality management protocols.

- Mine Safety and Health Administration (MSHA) Standard: Certified by the U.S. Mine Safety and Health Administration, ensuring safety for use in demanding mining environments.

- DNV-GL Marine Standard: Vitillo hydraulic hoses are certified by DNV-GL, a prestigious ship classification society, allowing their use in various marine applications.

- Railway Standards (HL1, HL2, HL3): This certification confirms the products are suitable for use in the railway industry.

- EN 856 4SP/4SH Standard: Many Vitillo hydraulic hose series meet high-pressure European standards, such as the 4-wire spiral hose types.

- SAE 100R Standard: Vitillo manufactures various hoses compliant with the standards set by the Society of Automotive Engineers, including 1-wire braid (SAE 100R1AT) and 2-wire braid (SAE 100R2AT) types.

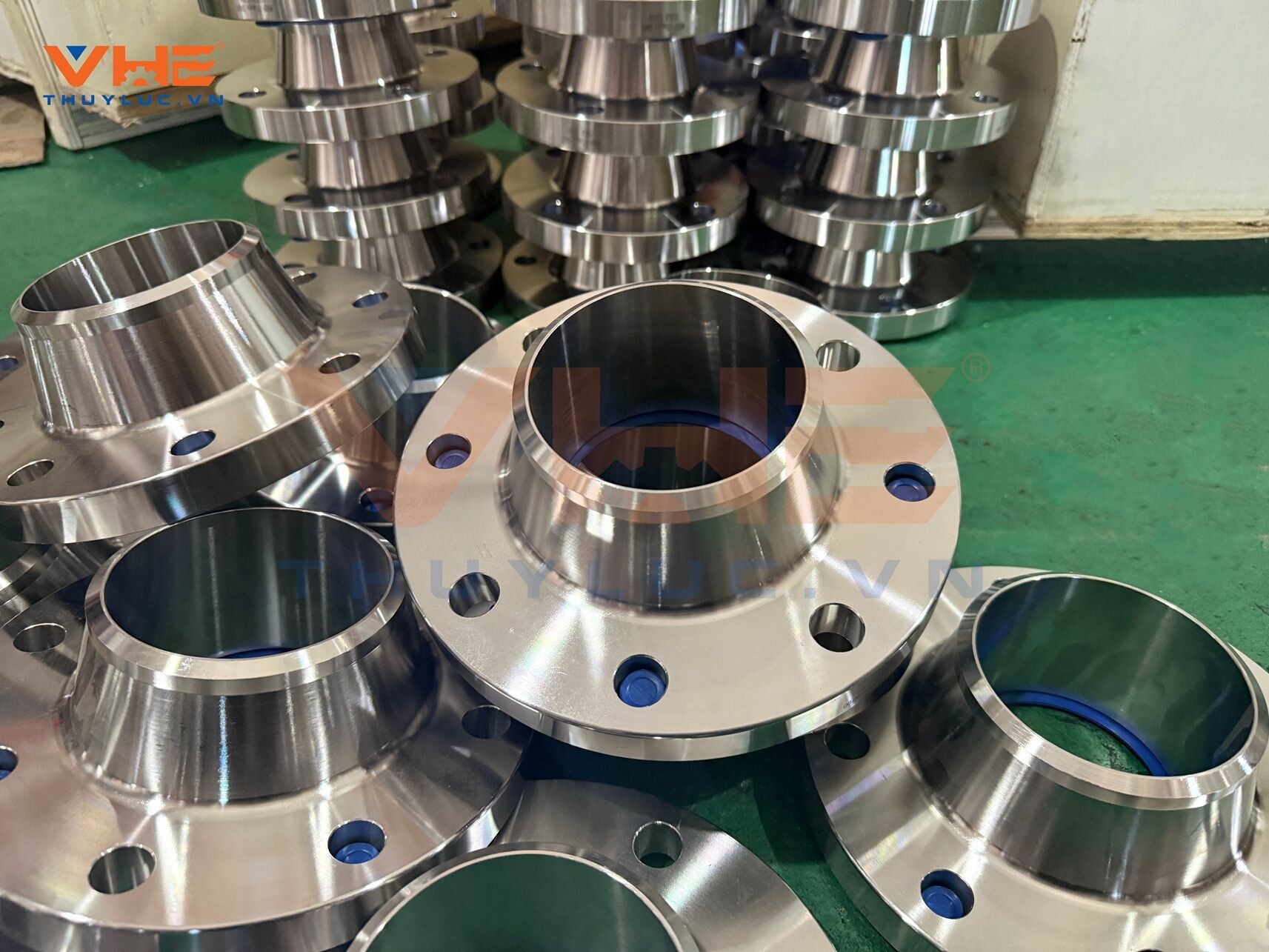

- Coupling Assembly Standard (ISO 12151 SAE J516): Vitillo's couplings and fittings are designed and tested to ensure high compatibility and performance with the company's hydraulic hoses.

Superior Construction of Vitillo Hydraulic Hoses

To meet these demanding standards, Vitillo hydraulic hoses are manufactured with a high-quality structure focused on durability, pressure resistance, and flexibility:

- Oil-Resistant Synthetic Rubber Inner Tube: Ensures excellent hydraulic oil compatibility and resistance to chemical corrosion. It is typically made from synthetic rubber, thermoplastic, or Teflon, offering flexibility and fluid compatibility.

- Reinforcement Layer (Wire Braid): Utilizing high-tensile steel wire braid (1SN, 2SN) or spiral wire (4SP, 4SH, R13, R15) enables the hose to withstand continuous working pressures from Medium to Extremely High.

- Outer Cover: Constructed from abrasion-, weather-, UV-, and ozone-resistant synthetic rubber to enhance the hose's ability to withstand high pressure.

- Operating Temperature Range: Wide, typically from -40℃ đến +100℃ (can reach +125℃ at peak), suitable for the climate and operating conditions in Vietnam

Choosing Genuine Vitillo Hydraulic Hoses in Vietnam

To ensure the purchase of certified, genuine Vitillo hydraulic hoses "Made in Italy," customers should seek out reputable distributors.

Vina-Hydraulic Equipment Joint Stock Company (VHE) is proud to be the official distributor of Vitillo S.p.a Group in the Vietnamese market.

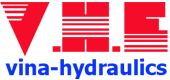

We supply a full range of Vitillo hoses, from 1-wire braid to 6-wire spiral (R13, R15), along with compatible couplings and accessories.

Commitment to Documentation: Products are guaranteed to come with complete documentation, CO (Certificate of Origin), CQ (Certificate of Quality), and supporting international certifications (MSHA, DNV-GL, RINA).

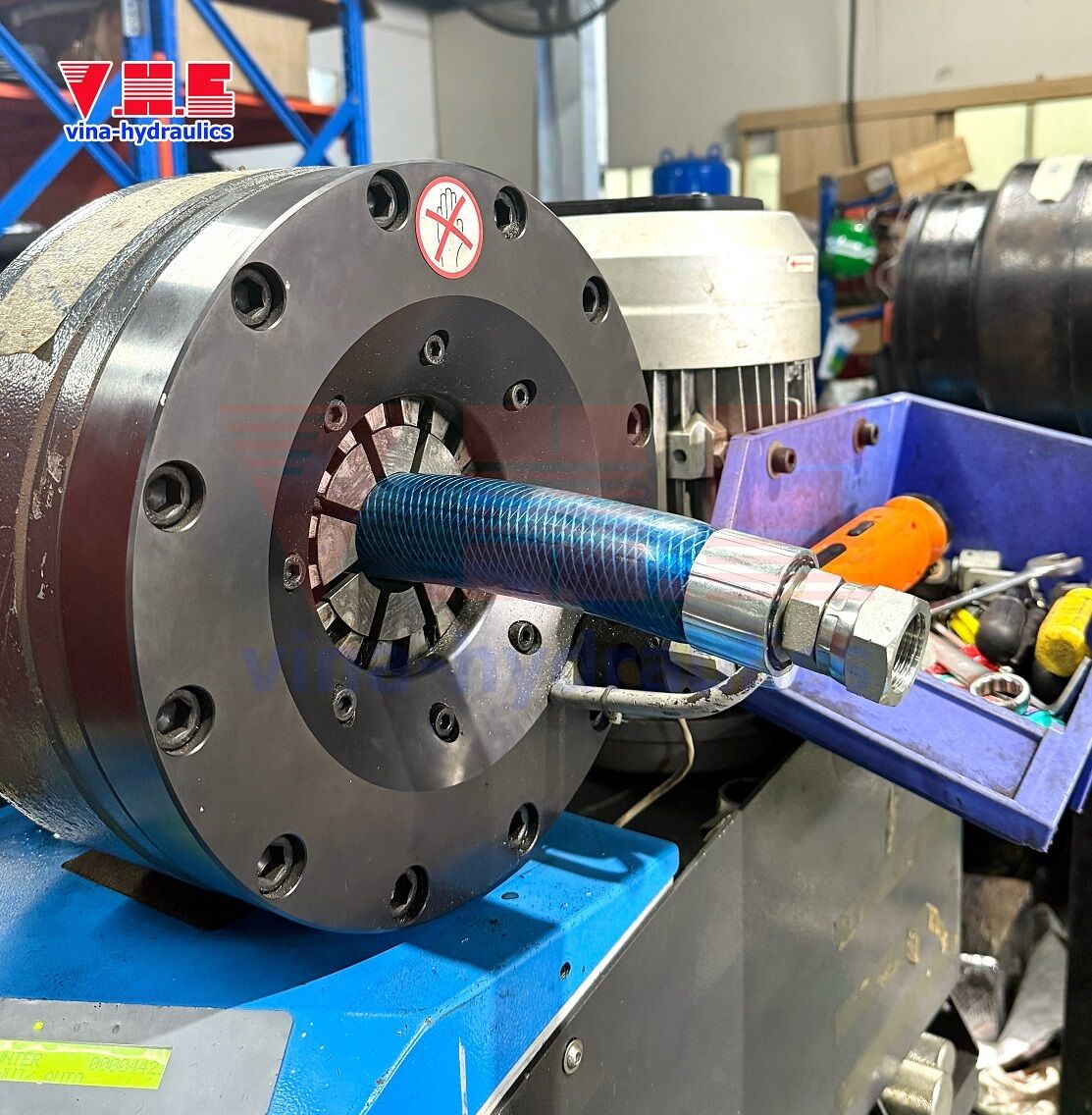

Expert Technical Support: VHE's highly trained technical team is ready to provide optimal solution consulting and perform the most precise hose crimping services according to the manufacturer's standards.

Transparent Invoicing: All transactions at the company include clear invoicing, ensuring legality and financial transparency. Customers will always receive all necessary documents for management and payment.

CONTACT INFORMATION:

- Consulting & Inquiry Support: 0903 967 588 - 0903 067 588

- Support Email: [email protected]

- Office Address: 31 D20 Street, Phuoc Long Ward, Ho Chi Minh City, Vietnam

- HCM Warehouse Address: Street No. 10, Song Than Industrial Park, Di An Ward, Ho Chi Minh City, Vietnam.

- HN Warehouse Address: Km28, National Highway 6A, Dong De Industrial Zone, Phu Nghia Commune, Hanoi City, Vietnam.