In hydraulic systems and heavy industry, seamless steel pipes are considered the "veins" that transmit energy. However, under budget pressure, many businesses opt for pipes of unknown origin or substandard quality.

The consequences go beyond equipment damage—they lead to devastating economic impacts and labor safety hazards. Let’s join VHE in identifying 5 "fatal" risks in the article below!

1. Cracking and Leaking Under High Pressure

Low-quality steel pipes often suffer from inconsistent wall thickness or impurities during the casting process. When the hydraulic system operates at high pressure, these "weak points" are amplified, leading to:

Longitudinal Cracks: Causing severe hydraulic oil loss.

Pipe Bursts: Resulting in an instant pressure drop and halting the entire production line.

2. Rapid Chemical Corrosion and Oxidation

Substandard pipes often lack essential alloying elements (such as Nickel and Chromium found in standard stainless steel). In harsh industrial environments or when exposed to chemicals:

Pipes rust from the inside out, contaminating the hydraulic oil.

Lifespan is reduced by 50–70% compared to genuine stainless steel pipes, necessitating constant replacements.

3. Destruction of Expensive Components (Pumps, Valves, Cylinders)

This is a major financial "pain point." When low-quality pipes rust or suffer from surface peeling, metal debris flows with the oil into the system:

Scratches pistons and cylinders.

Clogs control valves.

Damages hydraulic pumps. The cost of repairing these components is often dozens of times higher than the initial investment in a high-quality piping system.

4. Risk of Occupational Accidents

A hydraulic pipe burst under high pressure can release a high-velocity oil jet, which is extremely dangerous and can cause severe injuries to operators. By using substandard materials, you are putting your team’s safety at grave risk.

5. Production Downtime – Reputation Damage

Every hour of downtime costs millions, or even hundreds of millions of VND. Using non-compliant steel pipes leads to frequent minor failures, delaying orders and damaging your business's credibility with partners.

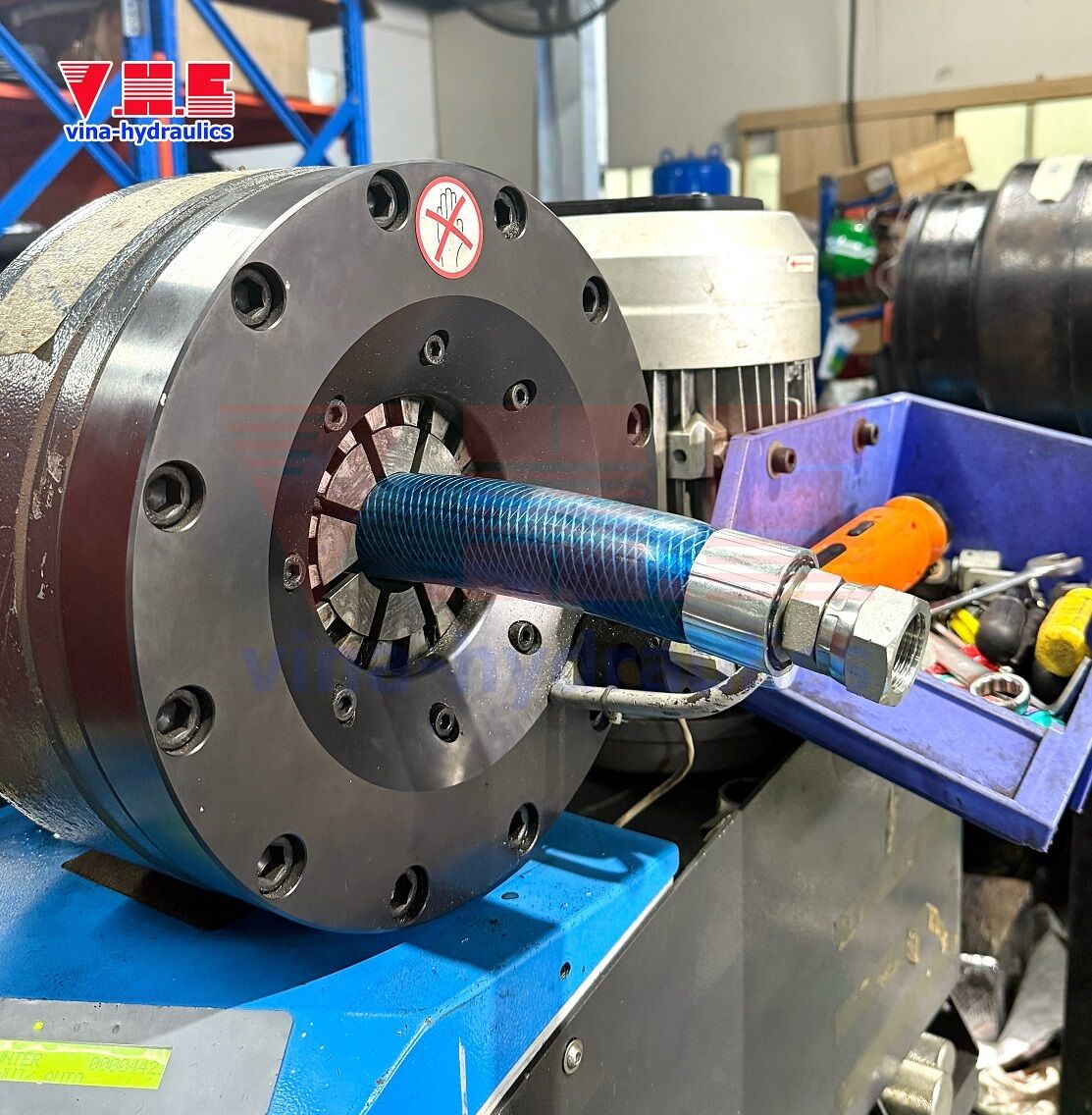

VHE's Solution: Specialized Seamless Steel Pipes for Hydraulic Systems

Recognizing these risks, Vietnam Hydraulic Equipment Joint Stock Company (VHE) provides premium seamless steel pipes trusted in heavy industry, shipbuilding, and oil & gas.

Why choose VHE’s seamless steel pipes?

- Superior Materials: Stainless steel (SUS316) with excellent corrosion and heat resistance.

- Strict Standards: ASTM A 213/269 TP316/L POLISHED.

- Extreme Pressure Resistance: Specially designed for continuous hydraulic operations.

- Outstanding Durability: Smooth surface finish, free of impurities, ensuring maximum protection for pumps and valves.

- Full Certification: Transparent origin with comprehensive CO/CQ meeting strict international standards.

"Expert Advice: Don't just look at the purchase price; look at the operating cost per hour."

Need expert advice on the right seamless steel pipe for your system?

- Consultation & Support: 0903 967 588 - 0903 067 588

- Email: [email protected]

- Address: 127 Huy Can, Gia Hoa Residential Area, Phuoc Long B Ward, Thu Duc City, Vietnam.

VHE – Your partner in the durability of every hydraulic project!