Today, the crucial step of protecting hydraulic hoses with stainless steel mesh is often overlooked in construction and heavy-duty equipment applications. This is not simply a short-term cost-saving measure; it is, in reality, accepting enormous risks that can lead to severe financial, schedule, and safety consequences.

Do not trade safety and performance for neglect. The following consequences are virtually unavoidable:

1. The Risk of Costly Downtime

The Problem: Hydraulic hoses being chafed, cut, or burst due to impact are the leading causes of system failure. When a hose ruptures, the resulting leakage or depletion of hydraulic oil brings the entire system to an immediate halt.

The Damage: The cost of repairing or replacing the hose is a minor expense. The most significant loss is the equipment’s downtime. Every hour an excavator or crane is inactive on a construction site can result in tens of millions of dong (or thousands of USD) in operational losses and project delay penalties.

2. Hydraulic Oil Leakage—A Dual Threat

Safety Hazard: Hydraulic oil often operates at extremely high pressure and temperature. If a hose is torn, the hot oil can spray out, causing severe burns to operators or nearby workers and creating a risk of fire or explosion in flammable environments.

Environmental & Slip Hazard: Leaking oil contaminates soil and water, demanding expensive environmental cleanup costs. Simultaneously, oil on the ground or walkways creates a slippery surface, posing a serious risk of slip-and-fall accidents.

3. Reduced Overall System Lifespan

Unprotected hydraulic hoses are easily aged by UV rays, ozone, and weather elements, leading to replacement much sooner than their designed lifespan.

Furthermore, metal fragments and dirt can enter the system through tiny tears, damaging the hydraulic pumps, valves, and cylinders. This escalates the overall maintenance costs many times over the initial investment in a protective mesh sleeve.

Why Stainless Steel Mesh is a Necessary Investment

Therefore, stainless steel mesh for hydraulic hose protection is not a simple accessory but a mandatory investment to ensure safety, maintain continuous working performance, and maximize profitability in the construction and heavy-duty vehicle industries.

VHE: Your Partner for Custom Stainless Steel Mesh Solutions

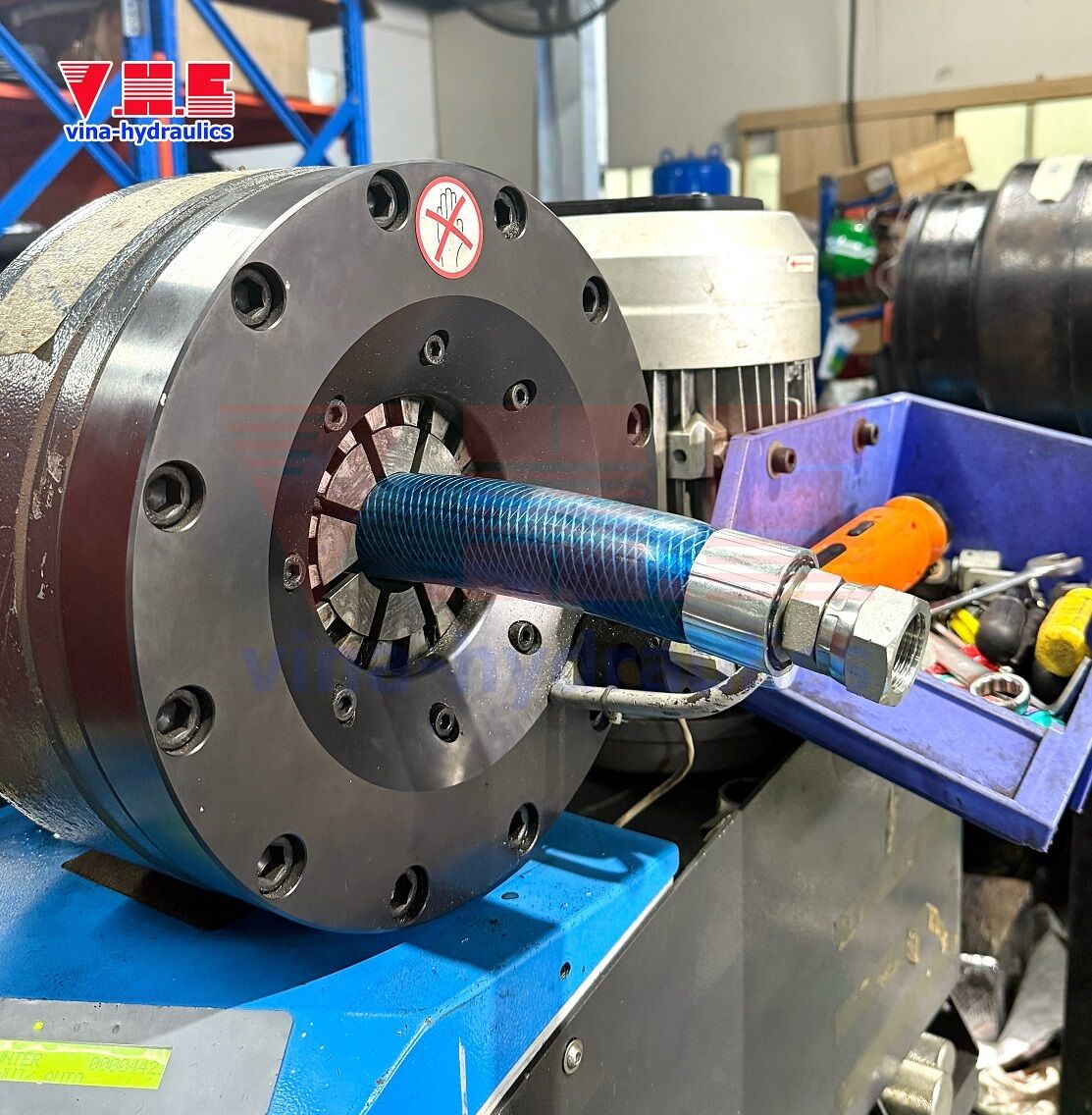

Currently, VHE’s workshop is equipped with advanced stainless steel mesh weaving machines to manufacture custom-braided sleeves for hydraulic flexible hoses and various other pipes according to customer needs. We process braiding for all types of flexible hydraulic hoses, corrugated pipes, etc.

Material: Stainless Steel 304—We use high-quality imported raw materials from POSCO with clear quality inspection certifications, manufactured on a cold-rolling line for excellent mechanical properties.

Production: Our modern, foreign-imported weaving machines offer a variety of sizes, ensuring high precision and excellent productivity.

Size Range (Braided Inner Diameter): From DN8 to DN80.

Available Stock Sizes at VHE:

- Elastic Stainless Steel Mesh, ID18, 3/8”, LI-ID18

- Elastic Stainless Steel Mesh, ID22, 1/2”, LI-ID22

- Elastic Protective Stainless Steel Mesh, ID34, 1”, LI-ID34

- Elastic Stainless Steel Non-Corrosive Mesh, ID42, 1.1/4”, LI-ID42

- Stainless Steel Mesh, ID49, 1.1/2”, LI-ID49

- Elastic Stainless Steel Mesh, ID73, 2.1/2”, LI-ID73

If you require stainless steel mesh to protect the hydraulic hoses in your systems, please contact VHE immediately for consultation!

- Consultation & Inquiry Support: 0903 967 588 - 0903 067 588

- Support Email: [email protected]

- Office Address: 31 Duong D20, Phuoc Long Ward, Ho Chi Minh City, Vietnam

- HCM Warehouse Address: Duong So 10, Song Than Industrial Park, Di An Ward, Ho Chi Minh City, Vietnam.

- HN Warehouse Address: Km28, National Highway 6A, Dong De Industrial Zone, Phu Nghia Commune, Hanoi City, Vietnam.