Stainless steel hose braiding is an absolutely essential component in numerous industrial and civil applications, serving as a comprehensive protective layer. Join VHE as we analyze the benefits of using stainless steel braiding in hydraulic systems in the article below!

Stainless steel braiding significantly enhances mechanical strength, effectively resisting abrasion, impact, and reducing vibration, thereby allowing the hose to withstand higher operating pressures. Crucially important for both hydraulic and flexible hoses, this stainless steel wrap also shields the hose from severe environmental factors such as high temperatures and corrosive chemicals. Thanks to these features, it ensures operational safety, extends the system's service life, and helps minimize maintenance costs.

Mandatory Applications for Stainless Steel Hose Braiding (Sleeving)

Equipping hoses with stainless steel braiding is a pivotal preventative solution in high-risk scenarios where durability and safety are the foremost priorities:

Aggressive and Extreme Environments: Essential in areas subjected to high temperature stress, exposure to sparks (such as furnaces, welding zones), or toxic volatile chemicals (petroleum/gas plants) to protect the hose from rapid degradation.

Fire Spread Control and Safety: Compulsory in facilities with strict fire safety regulations, including food and pharmaceutical plants, underground constructions, ships, and oil rigs, specifically to prevent the propagation of fire.

Enhanced Mechanical Protection: Utilized to defend against severe physical impacts such as continuous abrasion, heavy impact, or the risk of cutting/snagging from heavy machinery and rough terrains.

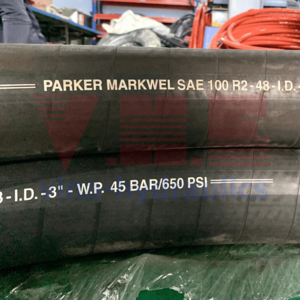

High-Pressure Systems: Critically important for hydraulic systems to boost pressure resistance, prevent sudden hose burst failures, and effectively reduce operating noise.

Operational and Personnel Safety Assurance: Plays a key role in preventing hazardous leaks and protecting workers from burn injuries resulting from contact with hot media.

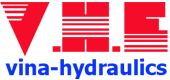

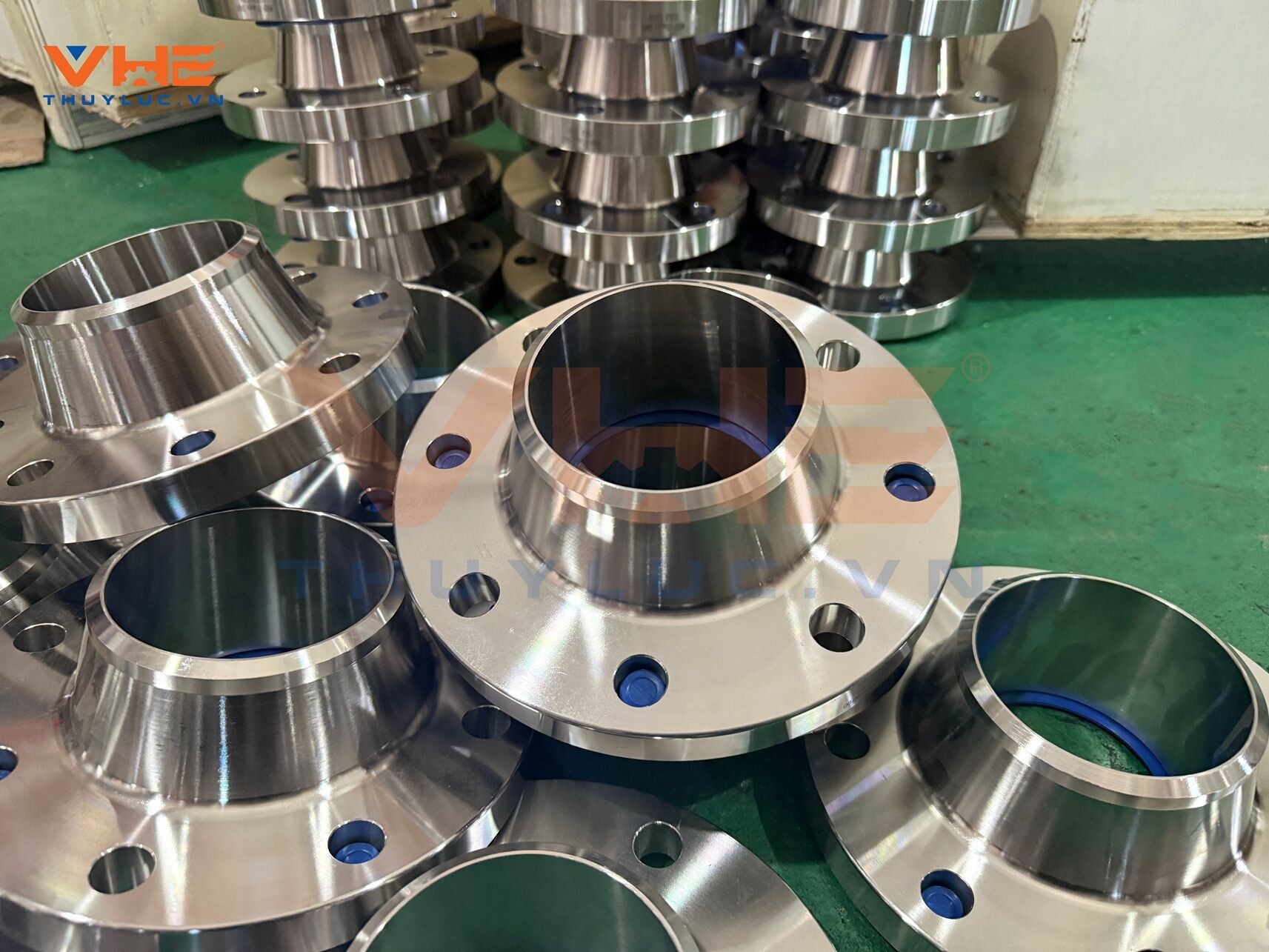

VHE's Stainless Steel Braiding Services

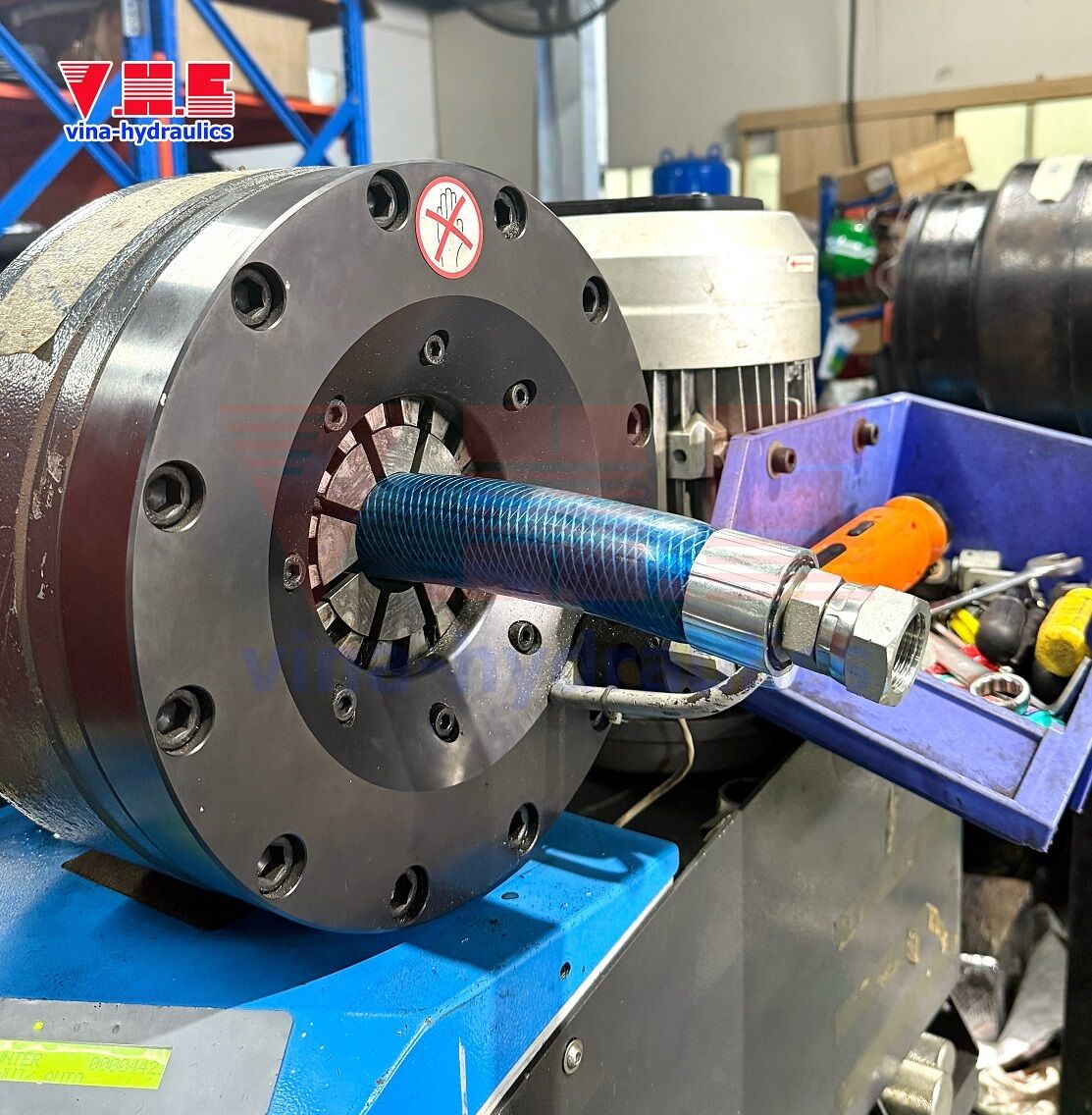

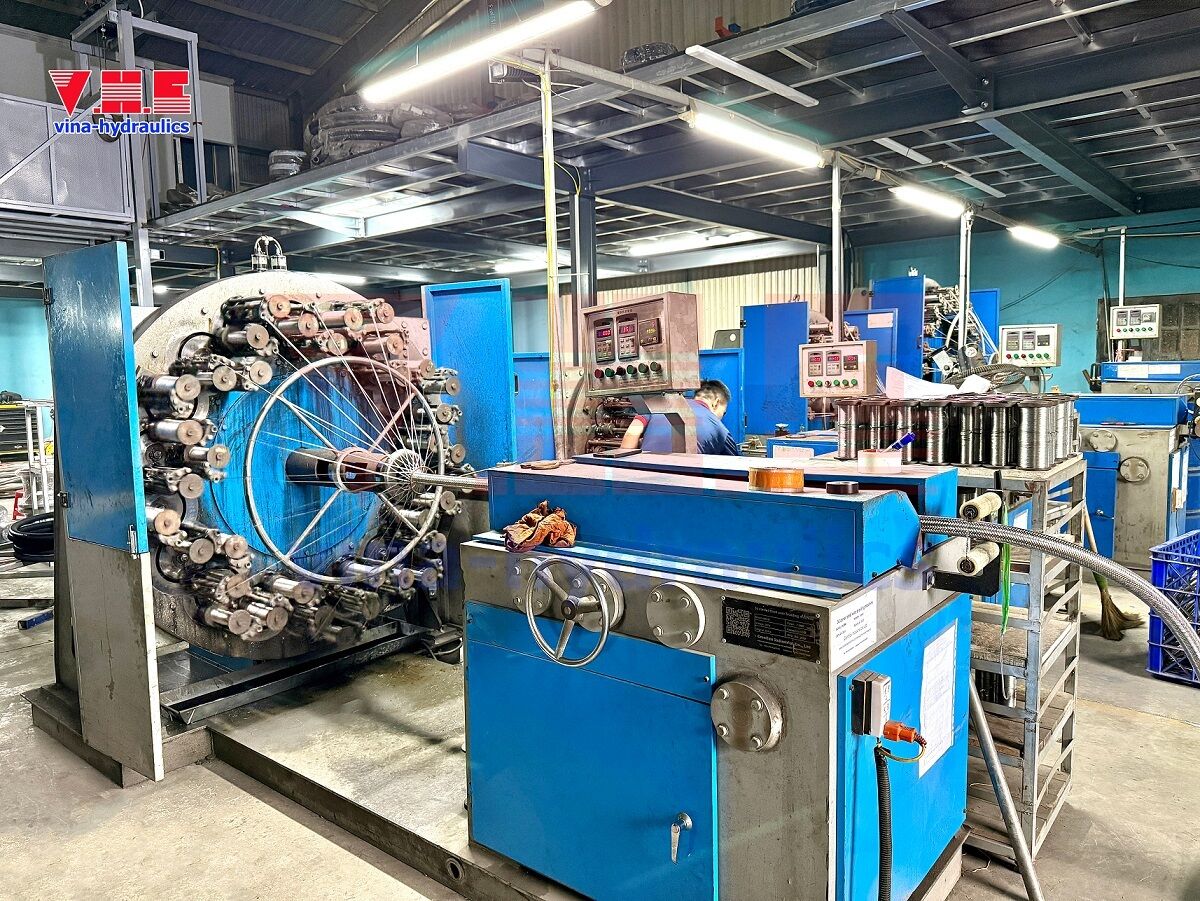

Currently, VHE's workshop facility has invested in stainless steel braiding machines to perform fabrication and custom braiding for flexible hydraulic hoses and other hose types according to customer specifications. We offer braiding services for flexible hydraulic hoses, corrugated hoses (flexible metal conduits), and more.

Material: Utilizing Inox 304, sourced from high-quality imported raw materials (POSCO brand) with clear quality certification (CO/CQ); manufactured using a cold rolling process for excellent mechanical properties.

Equipment: Our modern braiding machine systems feature diverse sizing capabilities, imported directly, ensuring high precision and excellent productivity.

Customers interested in purchasing stainless steel braiding or requiring custom braiding services for their hydraulic hoses should contact VHE immediately for consultation!

- Consultation & Inquiry Support: 0903 967 588 - 0903 067 588

- Support Email: [email protected]

- Office Address: 31 Duong D20, Phuoc Long Ward, Ho Chi Minh City, Vietnam

- HCM Warehouse Address: Duong So 10, Song Than Industrial Park, Di An Ward, Ho Chi Minh City, Vietnam.

- HN Warehouse Address: Km28, National Highway 6A, Dong De Industrial Zone, Phu Nghia Commune, Hanoi City, Vietnam.