Welding Neck Flange (WNF) is a widely utilized component in high-pressure piping systems across various industries. In this article, Vina-Hydraulic Equipment Joint Stock Company (VHE) will provide you with an in-depth look at its key characteristics, classification, and practical applications in modern engineering.

1. What is a Welding Neck Flange? Structural Characteristics

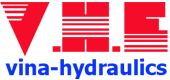

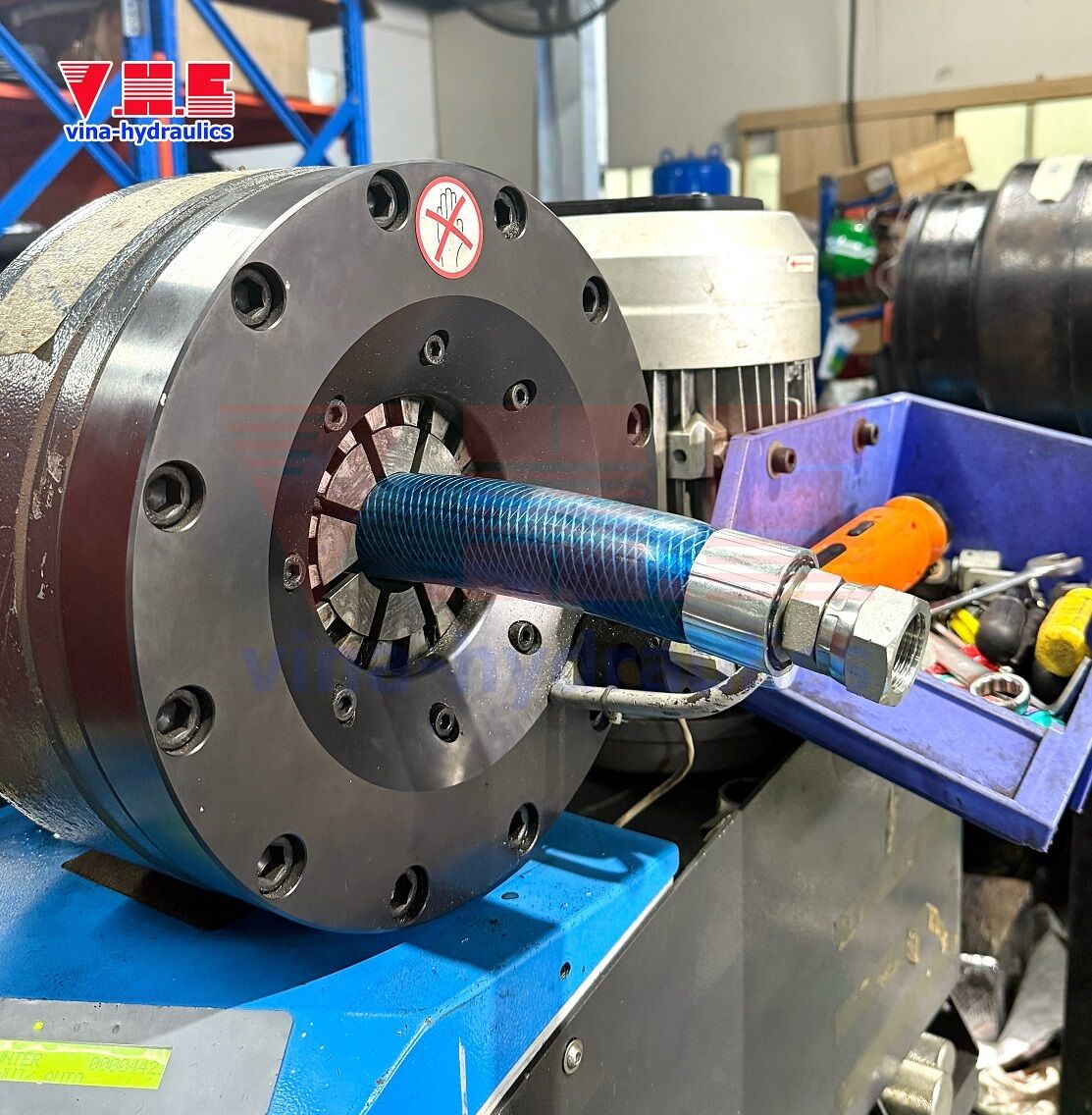

A Welding Neck Flange (WNF), also known as a high-hub flange, is distinguished by its long, tapered hub that is butt-welded directly to the pipe. This specific design ensures that the weld seam is fully exposed, making it exceptionally convenient for non-destructive testing (NDT) such as Ultrasonic Testing (UT) or Radiographic Testing (RT/X-ray).

2. Common Classifications of Welding Neck Flanges

In the current market, there are two primary types: Reducing Welding Neck Flanges and Long Welding Neck Flanges (LWN). To select the correct flange for your hydraulic system, you should consider the following technical standards:

- By Manufacturing Standards:

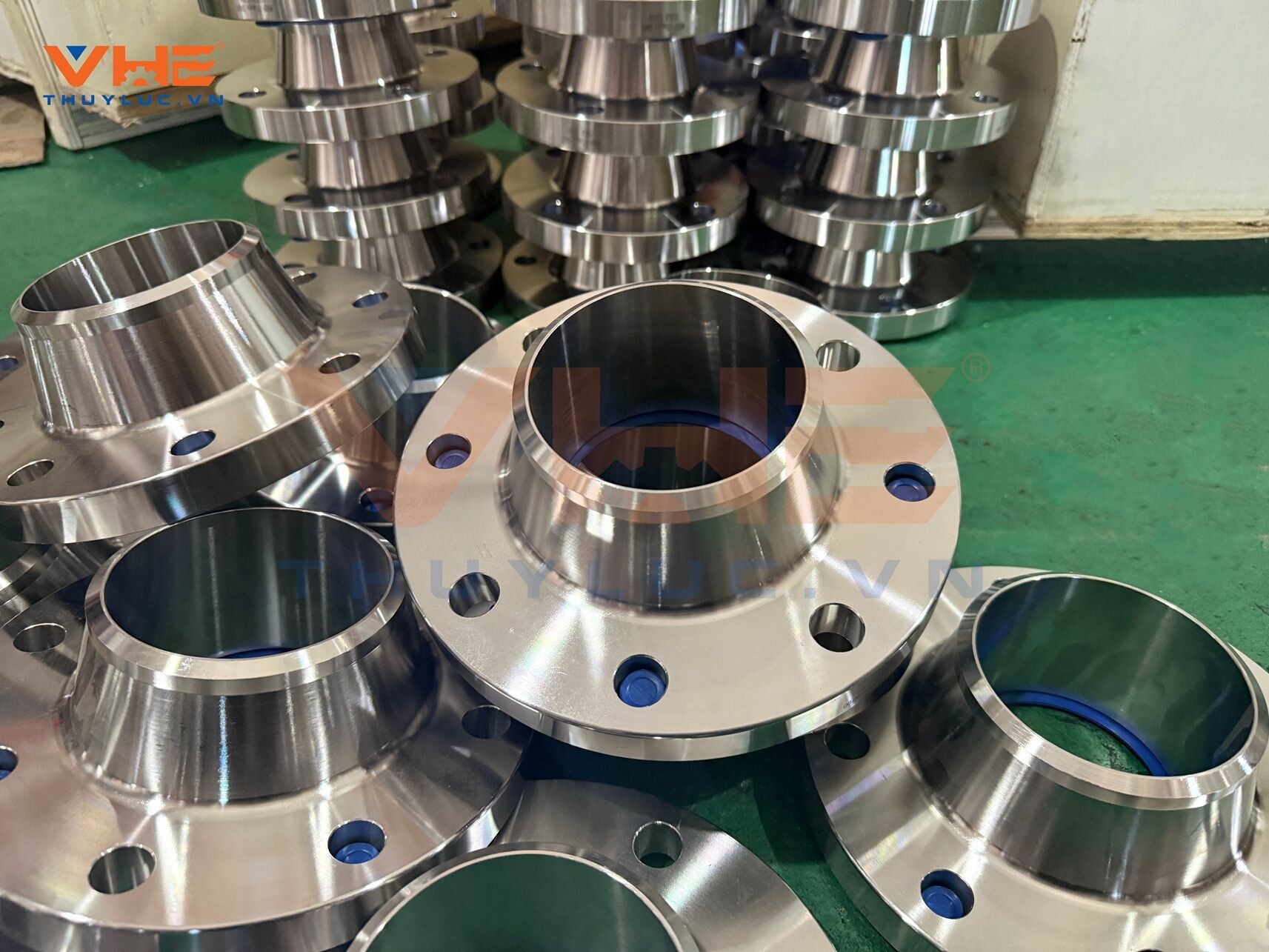

- American Standard: ANSI/ASME B16.5 (Class 150, 300, 600, 900, 1500, 2500).

- European Standard: DIN (PN10, PN16, PN25, PN40, etc.).

- Japanese Standard: JIS (5K, 10K, 20K).

- By Facing Type:

- RF (Raised Face): The most common type used in industrial applications.

- RTJ (Ring Type Joint): Features a machined groove for a metal gasket, specifically designed for ultra-high-pressure systems.

- FF (Flat Face): A completely flat surface.

- By Material:

- Carbon Steel: ASTM A105 (the most widely used).

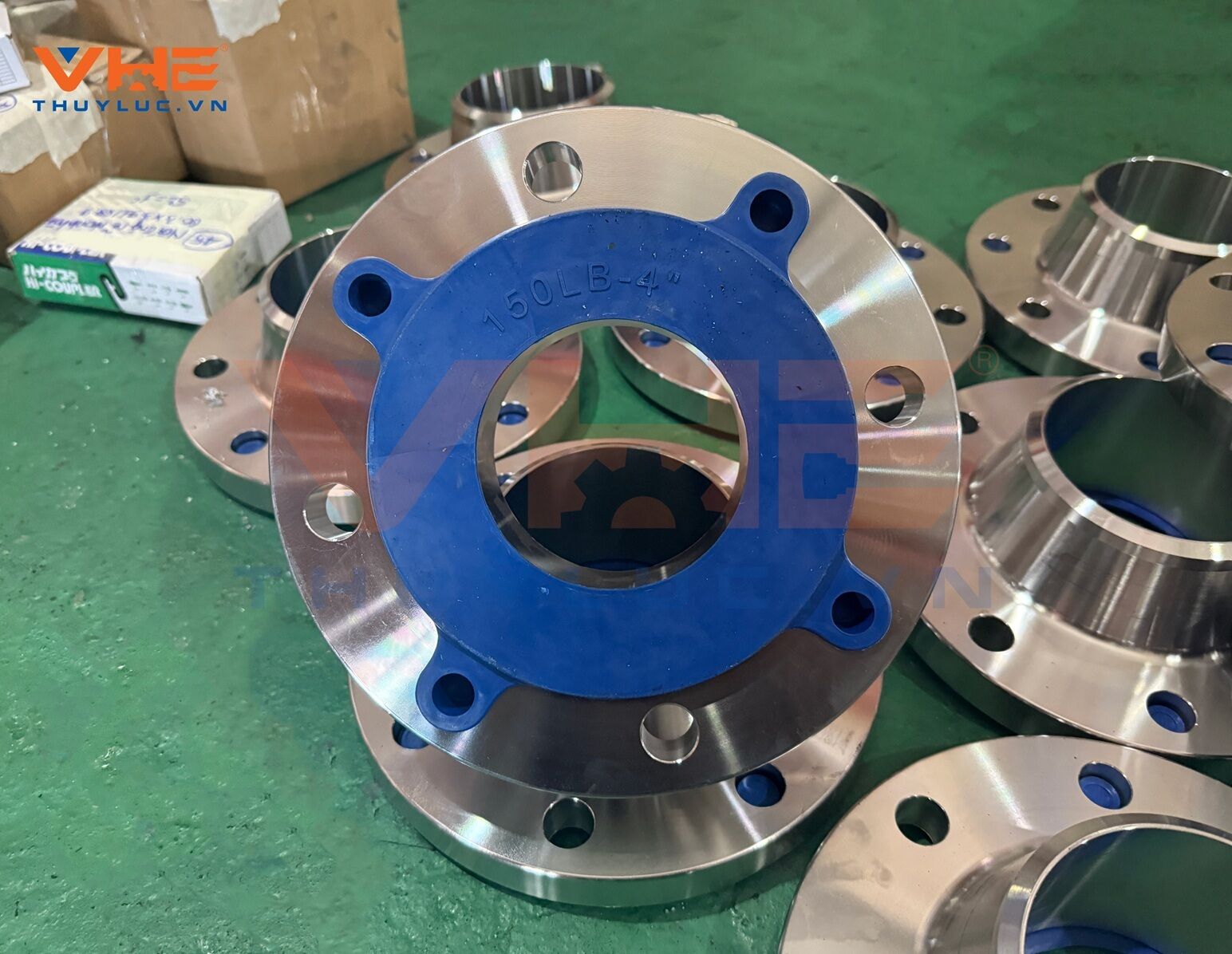

- Stainless Steel: SUS304, SUS316 (offering excellent corrosion resistance).

- Alloy Steel: For specialized high-temperature and high-stress environments.

3. Applications of Welding Neck Flanges

Thanks to their superior load-bearing capacity in harsh environments, Welding Neck Flanges are the top choice for:

- Chemical Systems: Handling acids, bases, and corrosive solvents.

- High-Tech Laboratories: Where precision and safety are paramount.

- Shipbuilding and Oil & Gas Industries: Demanding high structural integrity.

Conclusion If you are looking for a durable connection solution for high-pressure systems, the Welding Neck Flange is your optimal answer.

Contact us today for a detailed quote and a tour of our inventory.

- Consultation & Support: 0903 067 588

- Email: [email protected]

- Address: 127 Huy Can, Gia Hoa Residential Area, Phuoc Long B Ward, Thu Duc City, Vietnam.