Are you experiencing leaking hydraulic hoses that are reducing efficiency and causing cost loss? At Vina-Hydraulic Equipment Joint Stock Company (VHE), we understand that repairing leaking hydraulic hoses must be fast and precise and ensure absolute quality.

VHE is proud to introduce our Procedure for Handling Leaking Hydraulic Hoses, developed to high technical standards, helping customers restore machine operation as efficiently and sustainably as possible.

The 6-step Standardized Process for Comprehensive Leaking Hydraulic Hose resolution at VHE

Our procedure is designed to be streamlined, ensuring that all leakage issues are resolved completely (or thoroughly).

Step 1: Receiving the Old Hose and Recording Requirements

Objective: To gather comprehensive information regarding the hose's condition and application context.

Execution:

- VHE technicians receive the old, leaking hydraulic hose from the customer.

- Record and measure detailed basis parameters (length, diameter, and connector type) and information about the working environment, fluid type, and operating pressure.

- This is the crucial first step to identify the cause and propose the optimal replacement solution.

Step 2: Inspection, Evaluation, and Detailed Measurement

Objective: To accurately determine the location, extent of damage, and technical specifications.

Execution:

- Experienced technical staff conduct a comprehensive visual inspection, searching for cracks, abrasion, or blistering.

- Specialized measuring equipment is used to precisely measure crucial parameters such as inner/outer diameter, length, thread type, and thread angle of the connector.

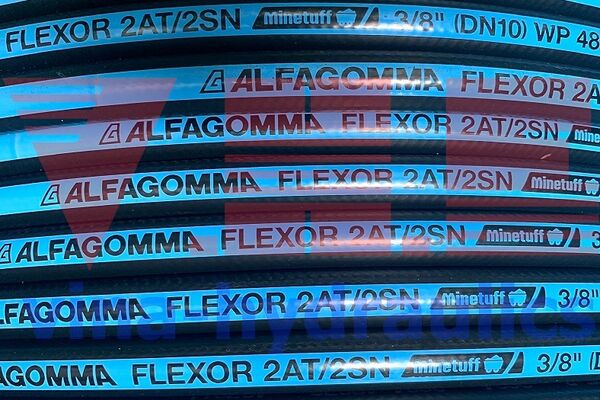

Step 3: Choosing the Appropriate Replacement Hose and Connector (VHE standard)

Objective: Ensuring that replacement materials are of high quality and absolutely compatible with the system.

Execution:

- Based on the measurement results and working pressure parameters, VHE technical specialists will select the genuine hydraulic hose that meets or exceeds the initial requirements for pressure and temperature resistance.

- The hydraulic connector is precisely chosen based on thread type, size, and material to ensure maximum tightness, preventing recurring leaks.

Step 4: Fabrication, Crimping, and Complete Assembly

Objective: Creating a new hose assembly with the highest accuracy and durability

Execution:

- Cutting the hose according to the measured length

- The specialized crimping machine is used to crimp the connectors onto the hose, with the crimping force strictly controlled according to manufacturer standards.

- The fabrication process ensures that the internal structure of the hose is not damaged, maximizing the product's lifespan.

Step 5: Safety Pressure Testing (Pressure Test)

Objective: To confirm that the new hose assembly is capable of withstanding the working pressure and test pressure without leakage or deformation.

Execution:

- Every hose assembly, after fabrication, must undergo a pressure test using a pressure testing machine.

- The hose will be checked with a trial pressure higher than the rated working pressure according to safety standards (typically 1.5 - 2 times the working pressure).

Step 6: Final checking, Packaging, and Delivering

Objective: To complete the procedure and ensure customers receive a perfect product

Execution:

- A final inspection is conducted on cleanliness, straightness, and technical specifications.

- Careful packaging is performed, and technical specification labels are attached.

With over 13 years of operation in the hydraulic industry, Vietnam Hydraulic Equipment Joint Stock Company (VHE) possesses a team of highly trained staff with advanced technical expertise and many years of experience successfully completing hydraulic hose crimping orders for various businesses, both large and small.

Customers needing hose replacement or experiencing hose-related issues during system operation should contact VHE to receive specific consultation from our highly experienced technical specialists!

CONTACT INFORMATION FOR SUPPORT

- Consultation & Inquiry Support: 0903 967 588 - 0903 067 588

- Support Email: [email protected]

- Address: 127 Huy Cận, Gia Hoa Residential Area, Phuoc Long B Ward, Thu Duc City, Vietnam