In the hydraulic system, pipe bursts are one of the headaches for many excavators. Subsequent maintenance and installation costs take a lot of time and money, and work performance will be delayed for a long time. So what are the common causes of broken hydraulic hoses? Let's find out from VHE through the post below!

1. Using the low-quality hydraulic hose

Currently, the market is distributing many hydraulic hoses from different brands. However, to get cheap prices, some people choose mistakenly poor-quality hydraulic pipes with low performance and durability. Moreover, after using it for a long time, the metal joints at both ends of the hydraulic hose have poor locking, leading to oil leaking out, affecting the entire production system.

2. Choosing the hydraulic hose with lower pressure than the hydraulic system

Choosing the wrong type of hydraulic pipe with a burst pressure different from the system will cause the probability of pipe breakage to be very high in the hydraulic system. will put additional strain on the engine, cylinders, hoses, and other system components. This can lead to increased wear rates, buckling between metal parts, and serious system failure.

3. The temperature of hydraulic oil is too high

If the hydraulic system operates at a high temperature, it can also cause damage to system components, causing broken pipes or leaks. Even if the oil temperature is too high, causing the valve core and valve body to become stuck, it will lead to an extremely dangerous hydraulic pipe explosion.

4. Mix different types of hydraulic oils

If hydraulic oil is added during use, the properties of the oil will be unstable, have high viscosity, and have poor fluidity. This will cause high pressure in the local part of the hydraulic system, easily causing pipeline leaks.

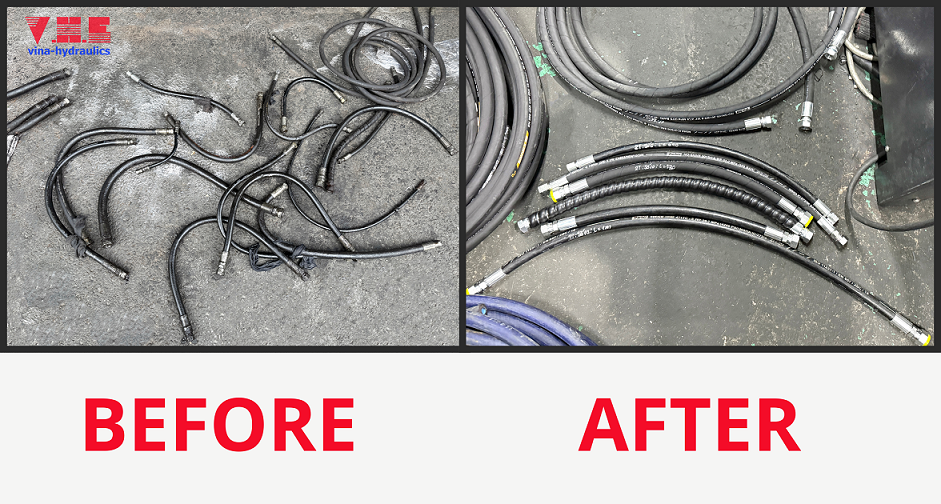

5. Wear and tear of hydraulic hose

Although today's hydraulic hoses are designed with a certain level of corrosion resistance and can withstand high temperatures, when rubber products come into long-term contact with diesel and gasoline, the rubber layer will swell, erode, and deteriorate. Therefore, in order to avoid diesel and other corrosive chemicals, the hydraulic pipes will be thoroughly cleaned of the outside surface.

6. Abnormal vibration of hydraulic hose

Both gear pumps and piston pumps have oil pulses when they work, which will cause high-frequency vibration of the hydraulic hose. Once the pipe is abraded by hydraulic pressure, not using a pipe clamp or using a poor-quality pipe clamp will wear it out for a long time.

Address for distributing high-quality hydraulic hose in Viet Nam

Vina- Hydraulic Equipment Joint Stock Company, located in Gia Hoa Residental Area, Thu Duc City, is currently an agent, and distributor specializing in providing genuine hydraulic hoses of many brands, such as Vitillo, Parker, Alfagomma, Sinopulse, etc., Viet Nam. VHE commits to providing full documentation and certifications of CO/CQ origin and comes with full warranty service, so you can feel secure when ordering here.

Refer to hydraulic hose products: https://thuyluc.vn/san-pham

Customers who want to buy hydraulic pipe products, please contact VHE for preferential quotes and specific advice!

Consulting support & Answering questions: 0903 967 588 - 0903 067 588

Support email: [email protected]

Address: 127 Huy Can, Gia Hoa Residential Area, Phuoc Long B Ward, District 9, Ho Chi Minh City, Vietnam